ERP for Industrial Manufacturing

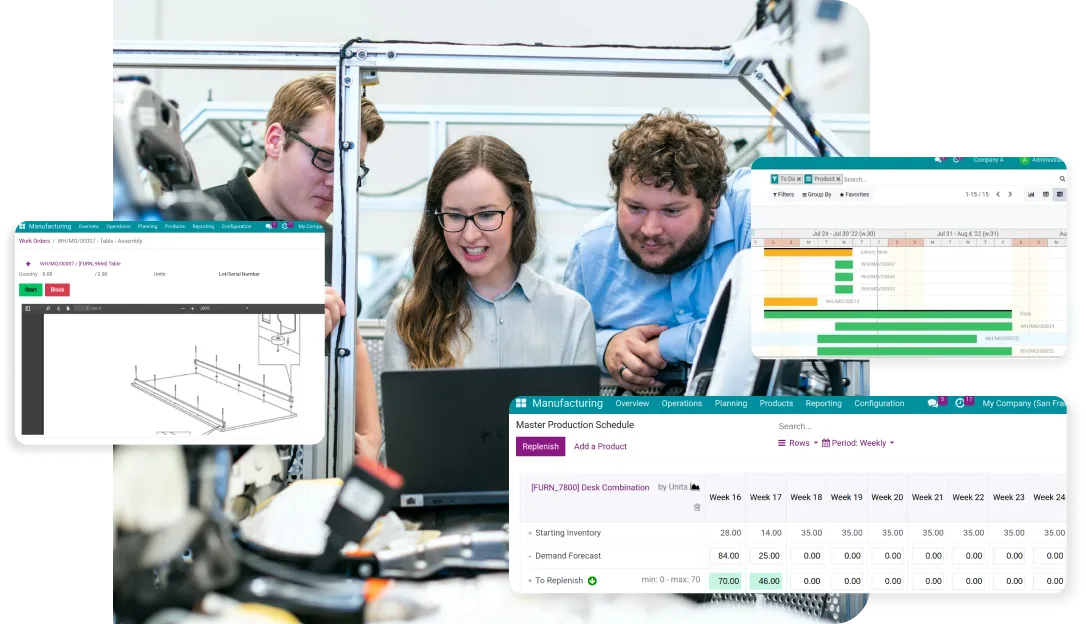

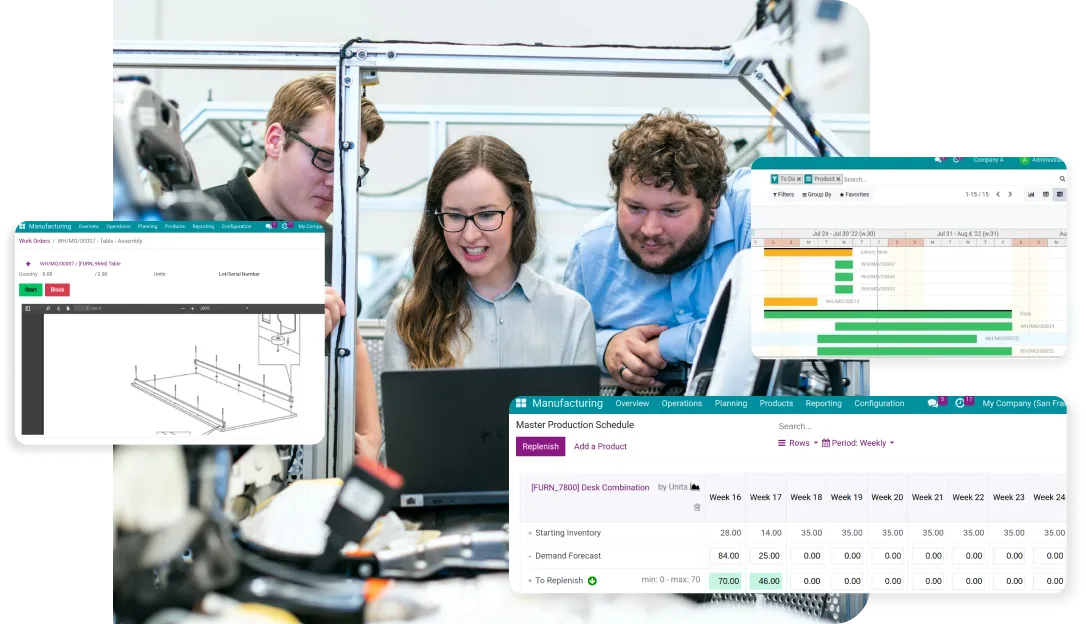

Viindoo ERP for Industrial Manufacturing - In-depth management solutions for the mechanical manufacturing industry.

Industrial Machinery and Equipment: lathes, milling machines, cutting machines, welding machines, electronic equipment, tools...

Mechanical Components; Transportation and Operation equipment (cranes, production lines, conveyors, motors, pumps, valves...)

Metalworking Products: from metal materials (steel, aluminum, copper) to machine components, parts...

Hơn cả một Phần mềm Quản lý Sản xuất cơ khí

Viindoo ERP giúp doanh nghiệp kiểm soát mọi hoạt động trong doanh nghiệp: từ quy trình sản xuất (sản xuất hàng loạt, sản xuất rời rạc (discrete manufacturing), sản xuất theo đơn đặt hàng), gia công cơ khí, MPS, kiểm soát chất lượng, tối ưu hóa tồn kho, mua hàng, kết nối với chuỗi cung ứng, CRM, quản lý tài chính, v.v.

ERP for Industrial Machinery, Equipment and more

More than an industrial manufacturing software, Viindoo ERP enhances production processes (mass production, job production, make-to-order production, batch production), mechanical outsourcing, MPS, quality control, optimizes inventory, purchasing, connects with the supply chain, CRM, financial management, etc.

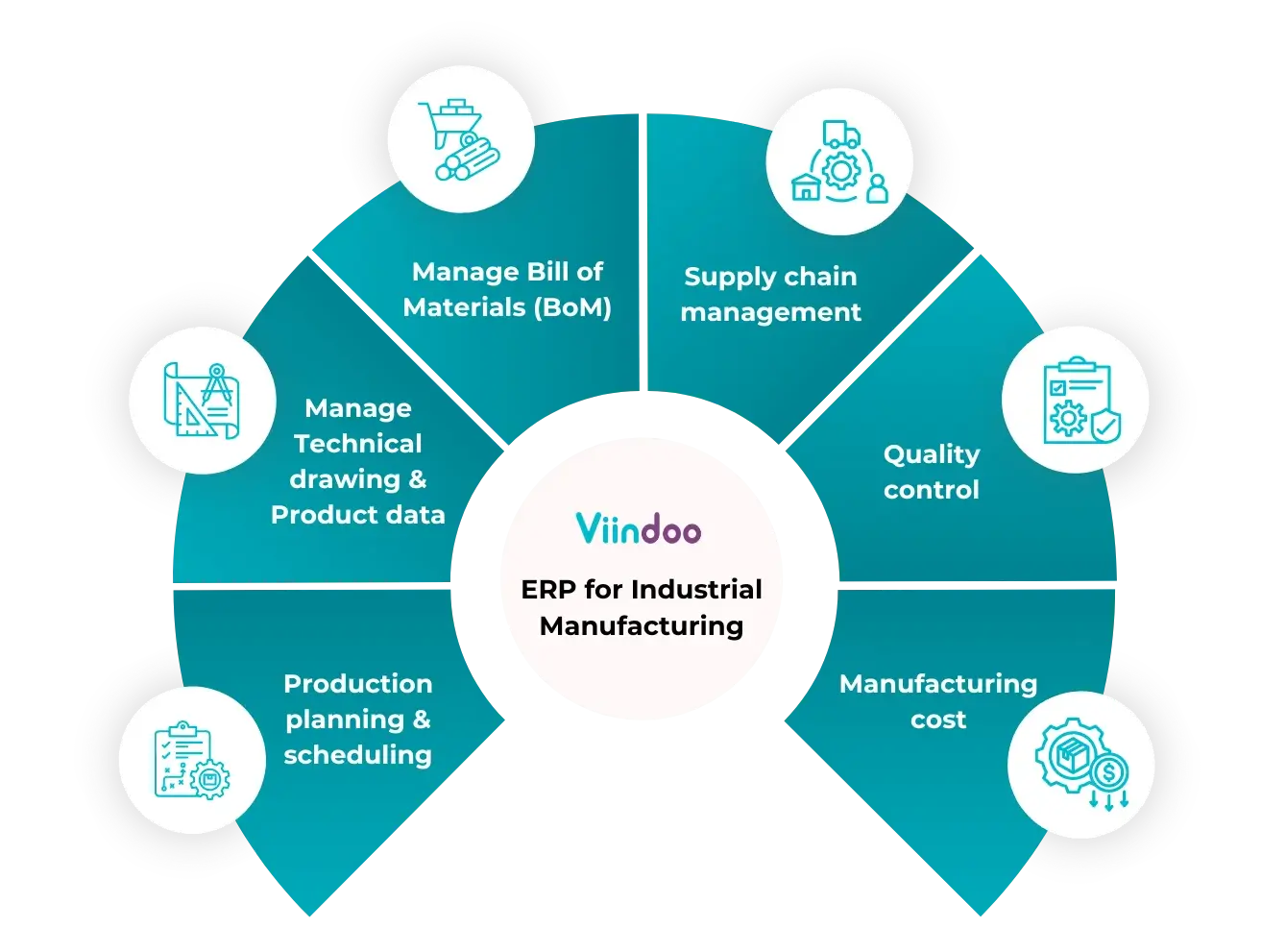

How can we help Mechanical Manufacturers

in efficiently managing and operating their manufacturing processes?

Production planning and scheduling

- Schedule manufacturing orders based on sales orders, inventory forecast, current production capacity...

- Forecast and manage resources such as machinery, labor, and necessary materials for production.

- Real-time production progress and inventory to adjust production plans as needed.

- Track production progress for each production order and per customer order.

Manage Technical drawing & Product data

- Manage technical drawings: detailed information on dimensions, materials, and other technical specifications.

- Manage product data: components, manufacturing processes, and specific technical attributes.

- Monitor product versions: design changes, technical information updates, and upgrade versions over stages.

Bill of Materials (BOM) management

- Build BoM for each product based on information from technical drawings and production processes.

- Flexible management of multi-level BoM to accommodate production processes from simple to complex.

- Calculate the quantity of materials needed based on the number of products to be manufactured and other factors (by-products, scrap materials).

- Compare actual material consumption with the plan.

Supply chain management

- Manage inventory and monitor material consumption at each stage of production.

- Automatic replenishment based on inventory or order requirements to supply materials timely, create additional production orders, transfer goods, and materials between warehouses/factories.

- Real-time detailed inventory reporting.

Quality control

- Control the quality of raw materials, finished goods, and products.

- Monitor and record quality parameters from the production process.

- Create quality alerts and provide preventive/corrective requirements during production.

Manufacturing cost

- Control input costs, labor costs, and general manufacturing costs.

- Collect manufacturing costs and allocate costs reasonably.

- Automatic reporting on manufacturing costs as a basis for calculating product prices.

Moving Towards the Smart Factory

Integrating discrete production stages (bending, cutting, welding, painting/plating, polishing...); collecting real-time production data.

Integration with third parties

Providing APIs to connect with customers' existing design software and management systems

No credit card required

An Viet Mechanical: JUST 4 WEEKS for 100% Employees use software in daily tasks

Viindoo ERP Software for Industrial Manufacturing

Manage industrial manufacturing with Viindoo Software

Manage all your warehouses

Deal with your Supplier

Manage product quality

Grow sales. Manage sales team

Planning & Scheduling, Report

Equipment maintenance

General Accounting, Costing

Product lifecycle management

Connect to internet of Things

Manage employee, salary

Real-time automated reports

No credit card required

Related Articles

Mechanical production management software - Viindoo MRP

Mechanical production management software was born to help solve the problems that the mechanical industry has been facing. Not only that, the software also improves the working efficiency of each department.

How to Calculate Manufacturing Cost: A Step-by-Step Guide

What is the manufacturing cost? This is an important expense for manufacturing businesses to ensure profitability and sustainable growth. In this article by Viindoo, we will explore in detail how to calculate manufacturing cost.

Product lifecycle management (PLM) in Viindoo software

Product lifecycle management (PLM) is one of the ways to help manufacturing businesses gain a competitive edge in today's fast-paced manufacturing industry.

FAQs

Viindoo software provides a full range of features for managing mechanical manufacturing businesses:

- Production management: MRP + MES + PLM + Quality + Maintenance + Warehouse

- Enterprise Operations: Human Resources, Payroll, Financial Accounting, Office Management, Sales Management, and Commercial Activities, etc.

Viindoo ERP for Industrial Manufacturing charges according to the actual number of monthly users, allowed access to all applications. Checkout here: Viindoo Pricing

With production activities, Viindoo provides a full range of reports:

- Work orders report;

- Manufacturing orders report;

- Overall Equipment Effectiveness report;

- Production Cost Report;

- Loss Components Analysis.

Got questions about how a ERP software can transform mechanical company?